A Project Sponsored by Avery Dennison

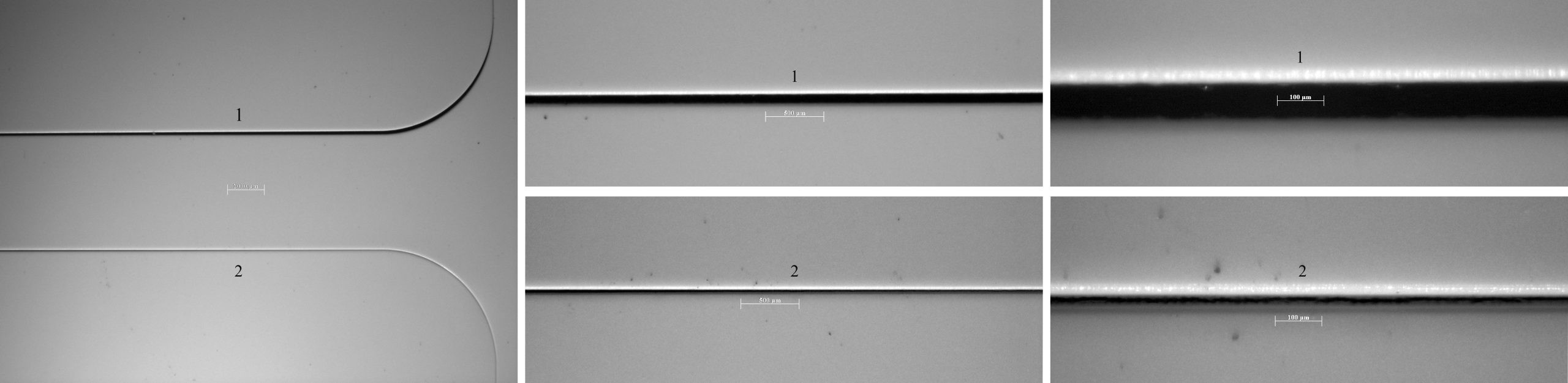

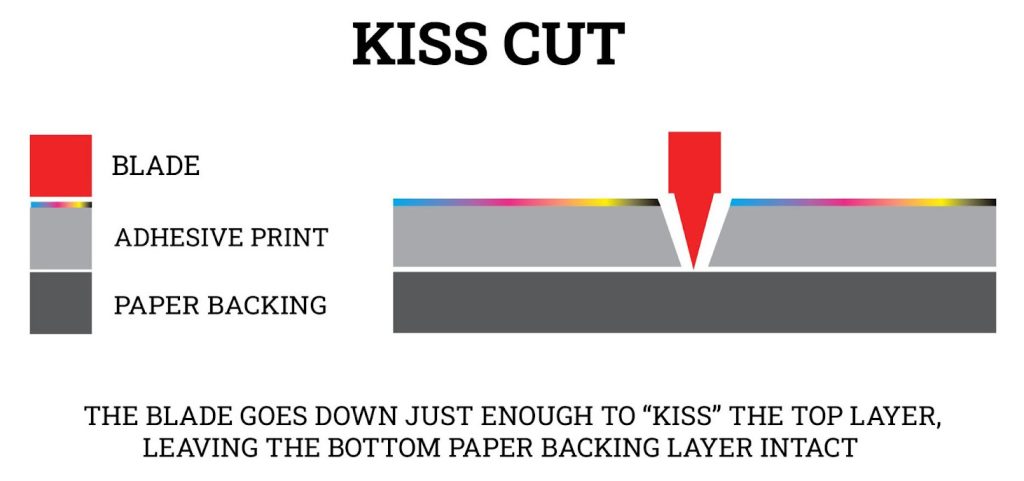

In packaging/labeling industry, high-speed precision die cutting is an excellent choice to create films/labels. A good cut usually means an easy separation of the label from the waste matrix. A kiss-cut of adhesive backed materials is commonly required in this application. The die cutting quality depends on three essential components: the cutting unit, the material it will cut, and the cutting tool.

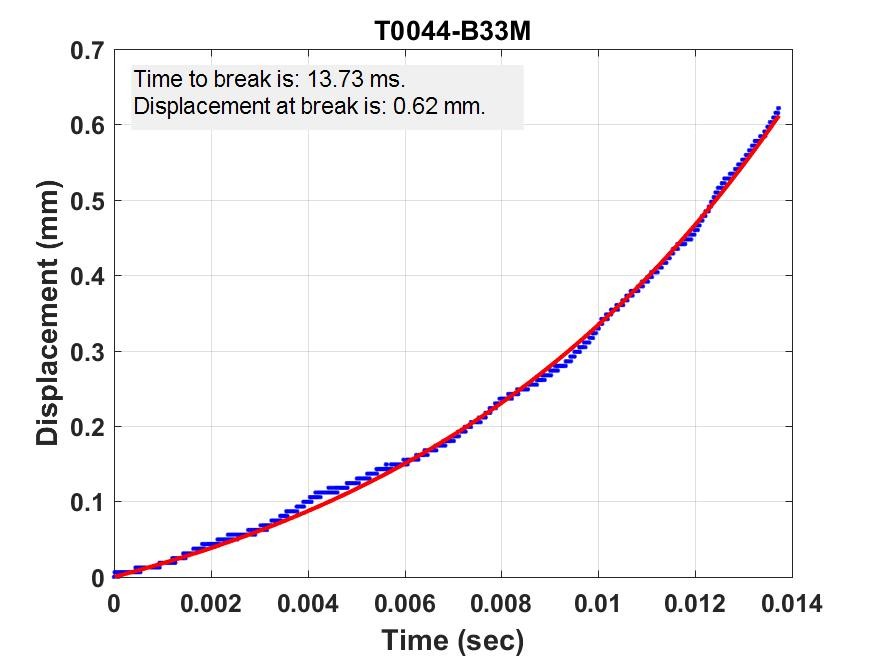

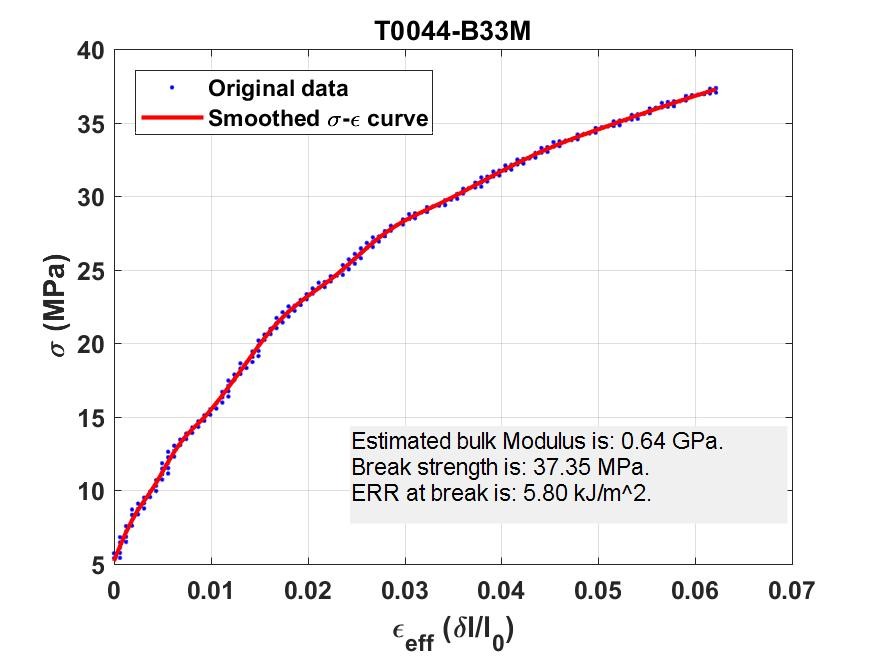

This project aimed to investigate the impact of material itself on die cutting quality. We designed a small-scale electro-mechanical desktop tester to measure the strength and toughness of the ligaments connecting the label with the waste. From test results, the following ranking parameters can be obtained: a) time to break; b) displacement at break; c) ligament strength at break; and d) energy release rate at break. Based on ranking parameters, a judgement of die cutting quality can be made.