A Project Sponsored by Avery Dennison

Conformability is a property of materials that allows them to conform to the contours of a curved or roguh surface. The lack of conformability of a thin plastic film lying on a non-flat substrate is commonly manifested in formation of blisters, wrinkles, and other forms of delamintion. Most of literature works have been focused on buckling-delamination or wrinkling, however, the following issues are not clearly addressed: (1) Which material parameters can be directly measured to quantify the conformability of the film; (2) Time dependency of buckling delamination; (3) The effect of adhesive properties. The purpose of this project is, if not impossible, to answer some of these questions, especially the time dependency of buckling delamination.

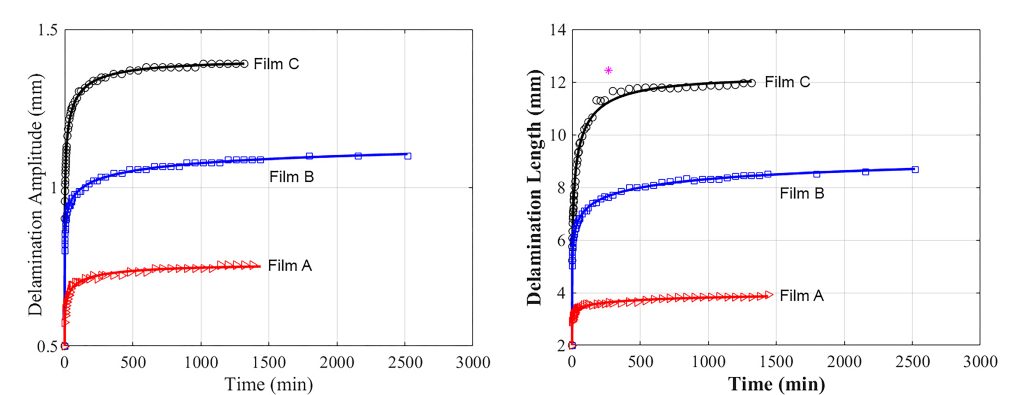

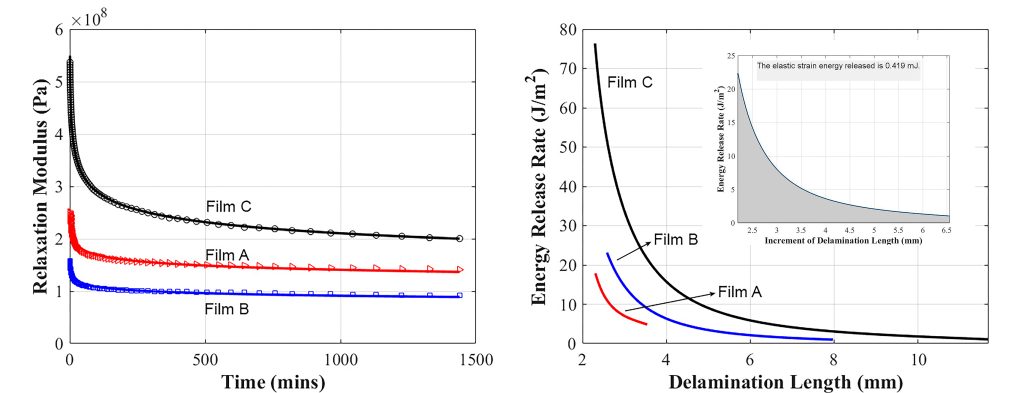

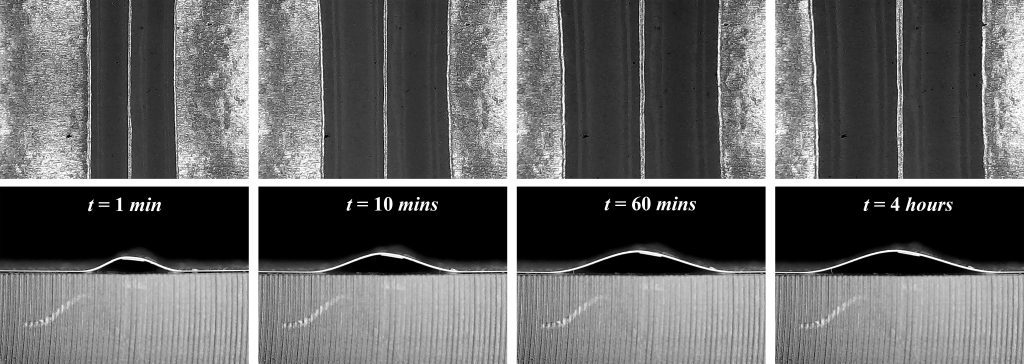

A release of the elastic strain energy accumulated within the film constitutes a driving part of a thermodynamic force of the delamination. Stress relaxation within the film under fixed displacement leads to a reduction of the elastic strain energy and hence of the thermodynamic force. Adhesive provides a resistive part of the force. Creep of the adhesive, initiation and growth of microdefects (such as microvoids) within the adhesive reduce the adhesive strength. In the continuum mechanics modeling, the adhesive strength reduction with time is formulated as time dependent specific energy required for delamiantion. A competition between the two mentioned time dependent processes results in a complex time-dependent buckling behavior that affects conformability of the plastic film.

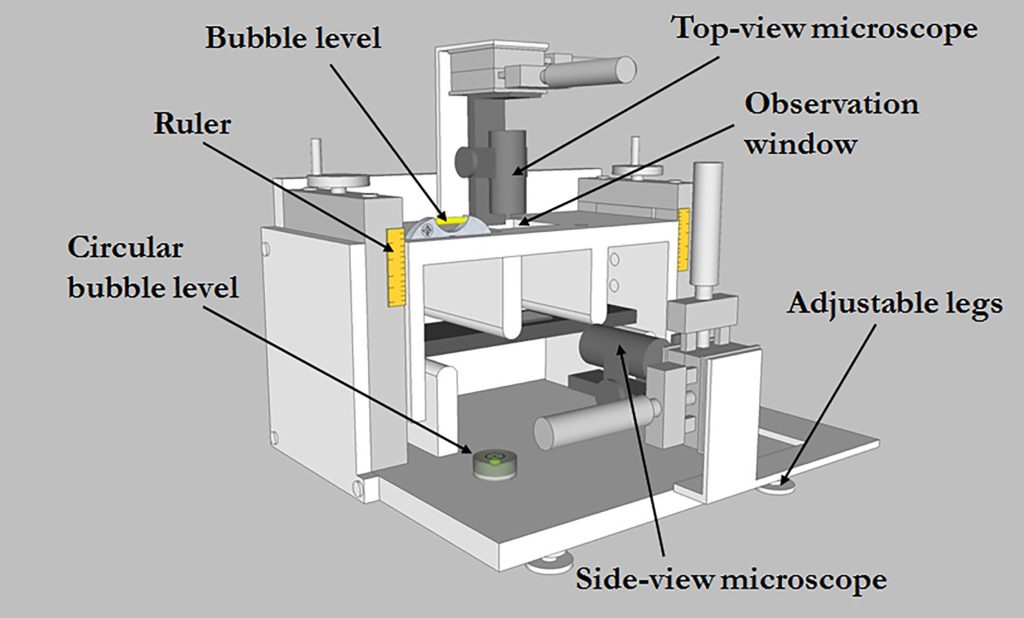

Our goal is to examine the film conformability and its variation with time and to develop an experimental setup for study of the film-adhesive-substrate systems. Therefore, we modified the four-point-bending test into a lab-designed and manufactured device called Conformability Tester. It accommodates a thick PE beam with the tested film attached on the top side. The front is open for operating sample and housing the side-view microscope. The top part has an open window that allows another microscope to monitor the growth of delamination from the top-view angle. Both microscopes are connected to and controlled by a computer.

Conformability Tester can record the delamination evolution. The energy release rates and delamintation energy are accordingly computed. The delamination energy represents the overall work done on adhesive in the process of blister growth. It also reflects the film ability to accommodate deformation without delamination. We propose the delamination energy as a single conformability parameter that incorporates several contributing factors. The delamination energy provides a quantitative tool for estimating the quality of conformability of plastic thin films.