A Project Sponsored by Shell & Total

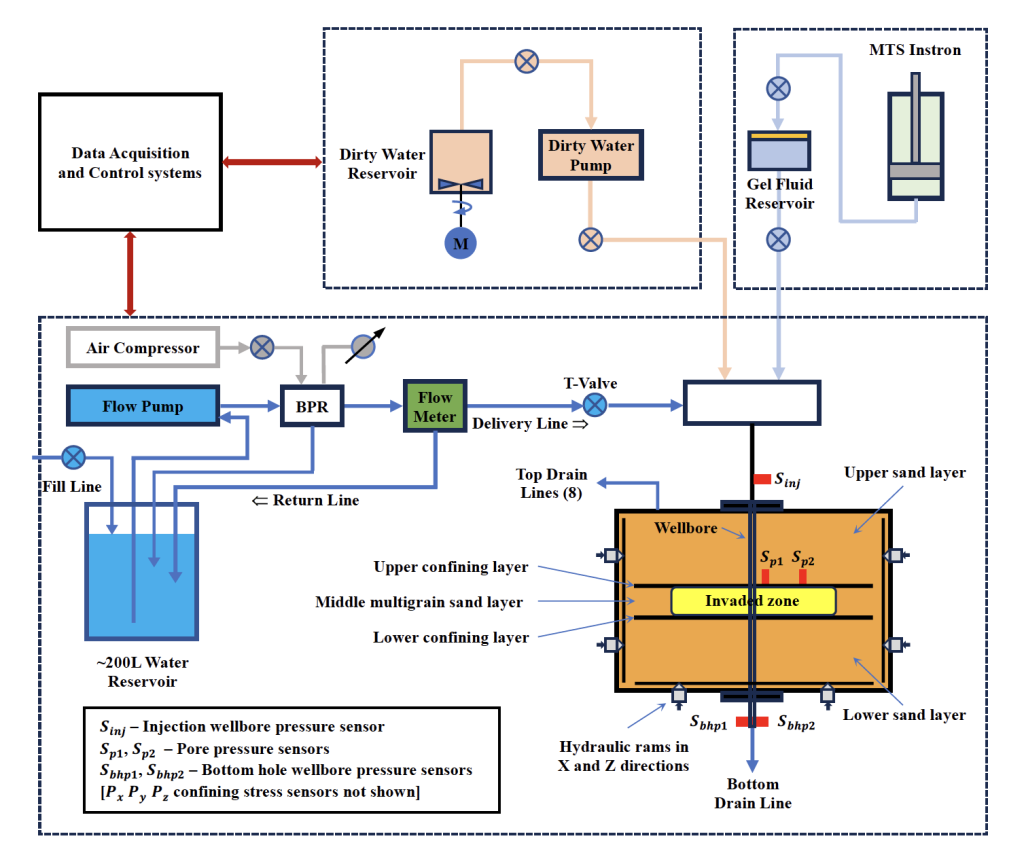

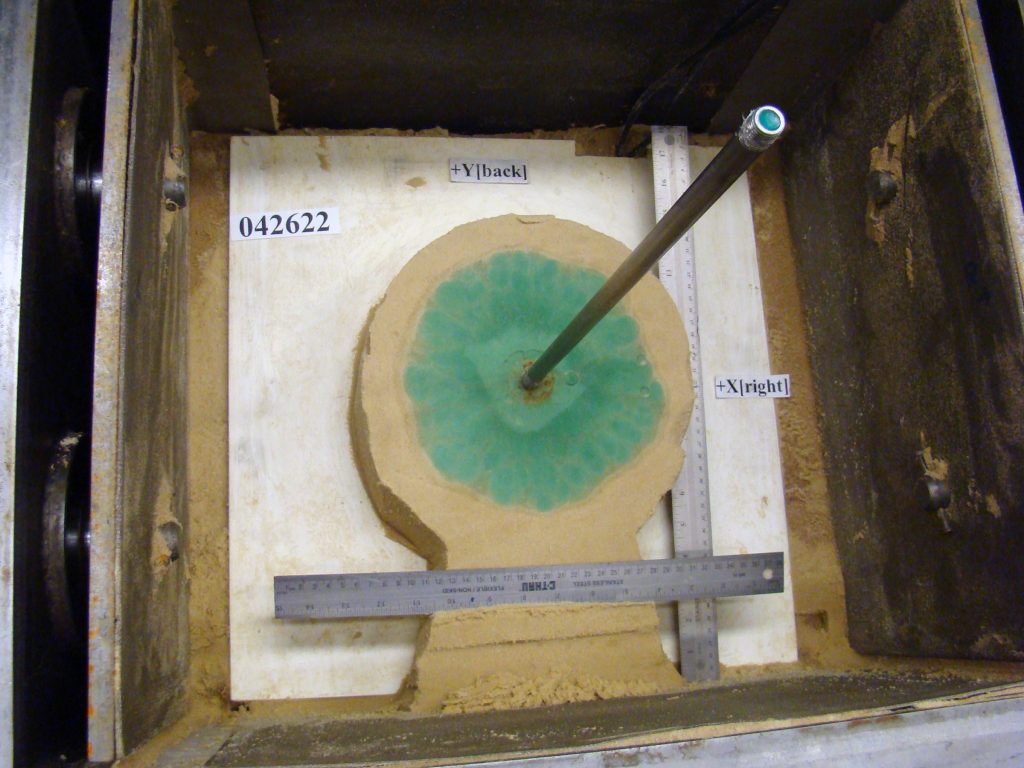

To gain new insights and improve performance of injectors, we conducted experiments to study the design factors of wellbore configurations, quality of injection fluids, injection conditions, and water hammer. The experiments used the cubic cell, sand pack injector with 3-D confining stresses. We delivered a comprehensive set of experimental data (injection rates, pressures, and preserved fluid invaded zones) to assess the impacts of:

a. Water hammer pressure pulses on injectivity and textural changes in the fluid invaded zone and provide test data to calibrate the water hammer models. Results can help selecting and developing improved water hammer mitigating solutions in areas of injection operations, downhole check-valves, and sand control completion.

b. Water quality in terms of solids or “dirty” water injection on injectivity and textural changes in the fluid invades zone and provide data to develop and calibrate solids plugging model. Results can lead to new insights on solids plugging mechanisms and deliver improved water quality specifications for different injector designs.